| Typical curriculums |

|

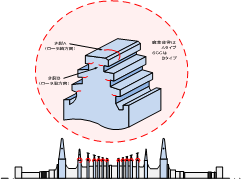

➀ USC-Boiler Maintenance (Standard period:3.0days) – Where is the weak point of coal-fired boiler? – |

Contents

The participants will learn the basic knowledge for boiler maintenance such as boiler structure and damages caused by aging.

They will also learn some points for long-term and efficient use.

Promote understanding using cut models

The participants can learn by using the case of actual plant

|

|

➁ Steam Turbine Maintenance (Standard period:2.0days) – Where do you check during major inspection? – |

Contents

The participants will learn the basic knowledge required for maintenance such as turbine structure and principles.

Learning about standards of maintenance

Learning about some examples of trouble and its countermeasure

|

|

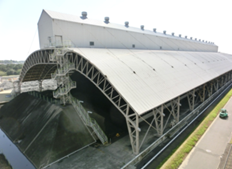

➂ Coal Handling (Standard period:3.0days) – What is needed to handle coal deliberately and safety? – |

Contents

The participants will learn coal blending technique and precautions regarding coal transportation and storage facilities.

They will also learn trouble cases and countermeasures for restoration and prevention.

The tour of the actual coal handling facilities of Chugoku EPCO

Learning examples of trouble and its countermeasures.

|

|

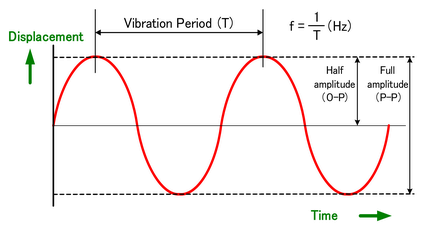

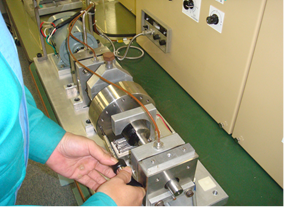

➃ Vibration Basic Technology (Standard period:3.0days) – Do you know vibration adjustment methods of rotary facilities? – |

Contents

The participants will learn the mechanism of vibration.

Theoretical study of vibration phenomenon

Practice with model rotors

|

|

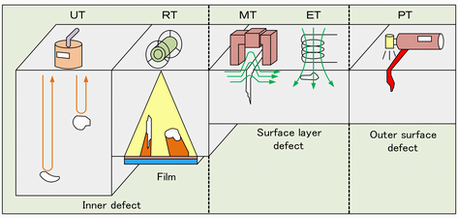

➄ Non-Destructive Testing (Standard period:1.5days) – Essential technology for finding the defect at inner or outer surface of material – |

Contents

Non-Destructive testing techniques are frequently used in thermal power plants.

The participants will learn these test principle and characteristics.

Differences and features of each testing method

Practice of MT

Practice of UT

|

|

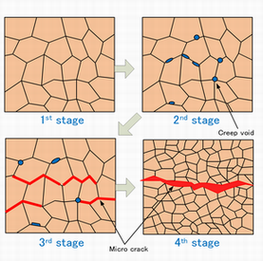

➅ Remaining Life Assessment (Standard period:2.5days) – How do you determine when the equipment should be replaced? – |

Contents

The participants will learn the mechanisms of aging of high temperature equipment such as boilers and turbines, and they will also learn characteristics and evaluation method of remaining life assessment.

Diagnosis of creep damage

Replica making

Observation of creep voids

|

|

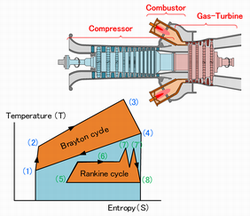

➆ Gas-Turbine Combined Cycle Power Plant (Standard period:5.0days) – Management techniques of Gas-turbine hot parts – |

Contents

The participants will learn basis of gas-turbine, hot parts management techniques and various trouble cases.

Learning basis of GTCC

Tour of the site under major inspection

|

|

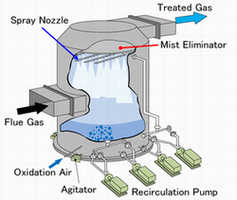

➇ Environmental Conservation Facilities (Standard period:2.0days) – In order to achieve harmony with the natural environment – |

Contents

The participants will learn the basic matters concerning environmental measures equipment of the latest technology of Japan, such as denitrification, desulfurization and waste water treatment equipment.

Learning about FGD

Site visit of actual Japanese Power Plant

|

|

➈ Boiler Water Quality Management (Standard period:3.0days) – Do you know that if the water quality were bad what impacts have occurred on the boiler? – |

Contents

The participants will learn the basic knowledge of desalting equipment and ion exchange resin.

Site visit of actual Japanese Power Plant

|

|

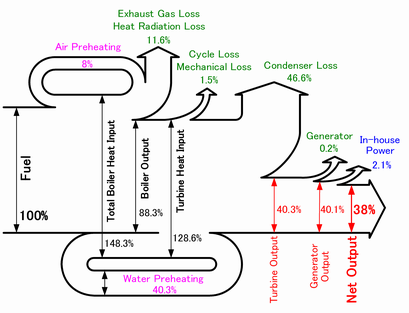

➉ Efficiency Management Technique (Standard period:1.0days) – How to maintain the thermal efficiency of your plant – |

Contents

The participants will learn efficiency loss factor and calculation method of boiler and turbine efficiency.

Understanding the energy loss factor and calculating the efficiency

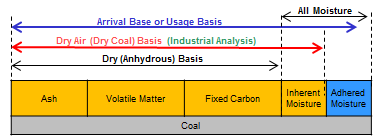

Understanding the relationship between the properties and the calorific value of coal

|